Cartridge Heater Description:

1. Cartridge heater consists of a cylindrical stainless steel tube and thus prevents itself from corrosion. The watt density can reach 25 W/cm2and the operating temperature can go up to 800°C (1472°F)

2. The cartridge heater is filled with magnesium oxide and compressed to avoid short-circuit. There is a heating wire inside which is wound into a ceramic core. The number of coils varies depending on the power.

3. Various cartridge heaters are available. We develop and manufacture cartridge heaters according to your special demands.

|

Model |

Dimension(mm) |

Voltage(V) |

Power(W) |

Key Technical Indexes |

|

LK-DD-Φ15Χ80 |

Φ15Χ80 |

380 |

400 |

1.Use condition: environment temperature -20~+60°C, Relative temperature <80%

2.Leakage current:<0.5MA

3.Insulation resistance:≥5M

4.Ground resistance:<0.1

5.Voltage resistance: no electric breakdown for 1 minute under 1500V

6.Temperature endurance:100-1200°C |

|

LK-DD-Φ20Χ155 |

Φ20Χ155 |

380 |

800 |

|

LK-DD-Φ16Χ200 |

Φ16Χ200 |

220 |

1000 |

|

LK-DD-Φ20Χ200 |

Φ20Χ200 |

220 |

1200 |

|

Note: Other models are available according to your specifications. Please refer to the Order Guide |

Cartridge Heater Specifications:

|

Diameter |

3mm to 30mm, etc. |

|

Length |

Customized |

|

Wire length |

Customized |

|

Leads type |

Direct line, SUS 304 braided, metal hose, etc. |

|

Voltage Supply |

12V to a maximum of 480V |

|

Total capacity |

customized |

|

Resistance Tolerance |

+10% - 5% (closer tolerances are available upon special request) |

|

Heating length |

Customized |

|

Sheath Material |

SUS 304/316/321 Incoloy 840 |

|

Insulation material |

Magnesium Oxide Powder |

|

Maximum Temperature |

800 °C

|

Cartridge Heating Elements Applications:

- Food processing

- Plastic moulds

- Medical equipment

- Hot stamping

- Liquid immersion

- Packaging equipment

- Labeling & Sealing

- Dies & platens

- Injection molding

- Nuclear industry

- Car industry

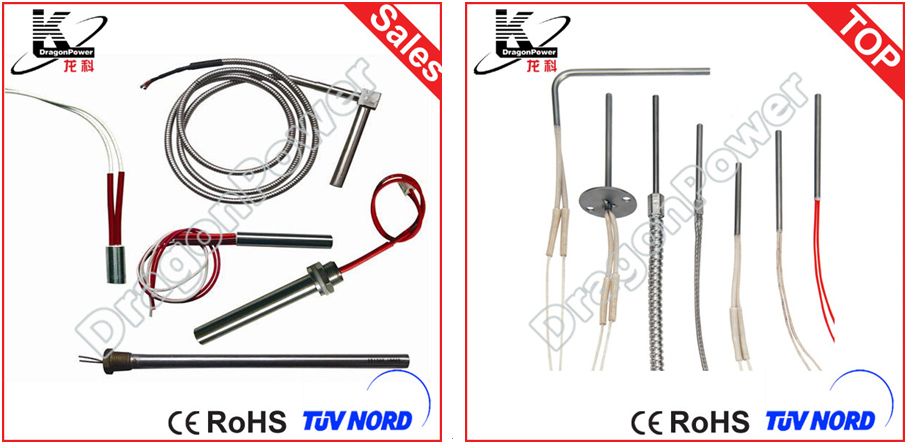

Cartridge Heating Elements Images:

Cartridge Heating Elements Production:

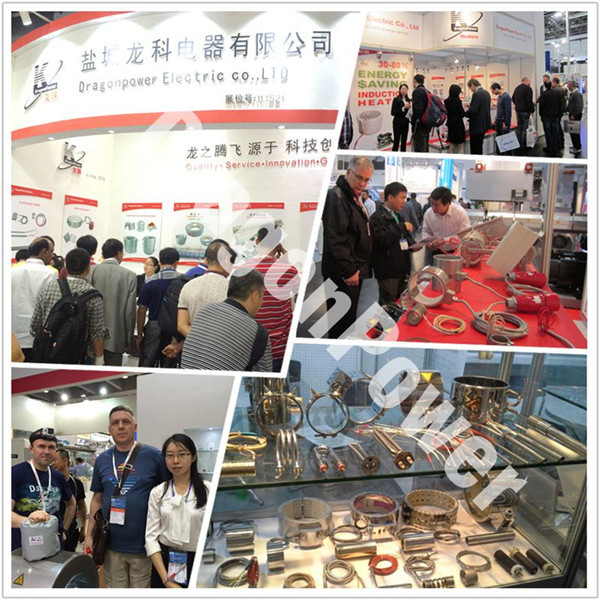

DragonPower Exhibitions:

Our Service

Order Guide

For Cartridge Heating Elements Orders, Please Specify:

1) Tube Diameter, Length, Volts/Watts

2) Material, Quantity

3) Lead option and length or terminal configuration, sheath material

4) Whether L shape

5) Heating length, working temperature, working environment

6) Lead end no-heat if different from standard

7) Optional accessories, finishing, internal construction

**Better to provide drawings/pictures

Certificates